preserve the silica gel pack saved together with your unused UltraColor Max transfers to keep humidity faraway from transfers

push: The well prepared movie is placed onto the fabric With all the printed aspect down. Using a warmth push, the movie is pressed onto the substrate of decision with the recommended application configurations.

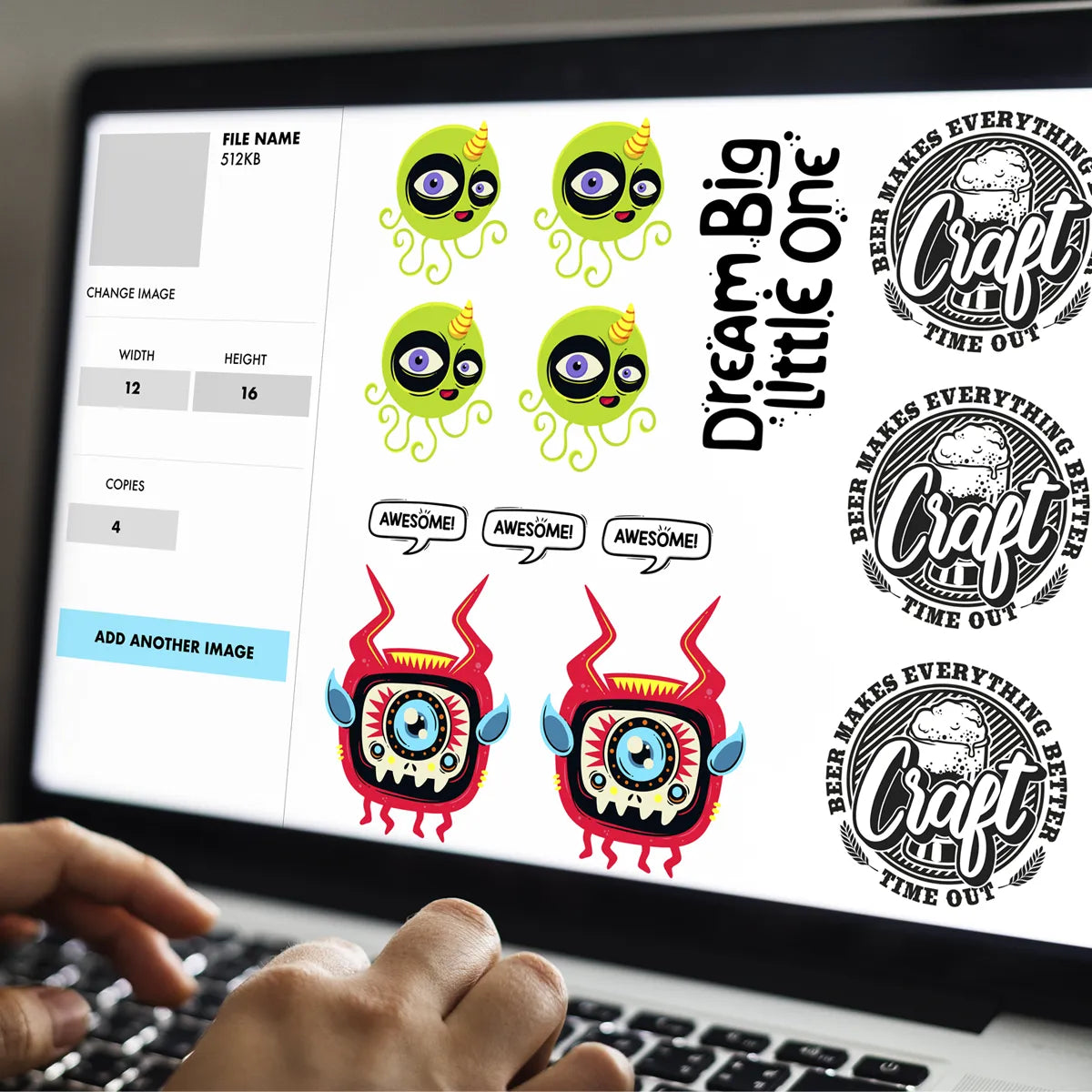

Pressing Your Transfers: All DTF transfers occur all set to press, so all you have got to do is stick to the appliance Recommendations for urgent on the clothes or items. More information on pressing your transfers are available further During this FAQ.

The placement of the heat transfer is Similarly significant, since it specifically impacts the visibility and harmony of the design. Heart chest placements draw attention and are perfect for fascinating graphics, even though left chest placements exude class and are frequently favored for corporate branding.

By adhering to straightforward dimension ranges for various print places, designers can make sure uniformity and regularity across several apparel sizes, from youth to Grownup selections.

As we’ve found, immediate-to-movie transfers offer you quite a few benefits for firms aiming to increase and succeed in nowadays’s aggressive Market.

Exactly what are the care Recommendations for DTF transfers? wait around 24 hours just before your very first wash, then use equipment wash chilly with mild detergent.

PET films are used in DTF printers. These films, having a thickness of 0.75mm, are exceptional elements that properly transfer your layouts on to items after applying warmth and tension.

considerably less squander: DTF transfers may also be an environmentally friendly selection, as they make a lot less waste than other printing approaches. a chance to print only what is necessary minimizes excessive content and ink use.

From smaller sized quantities and full colour printing to better stock management and a lot quicker turnaround periods, Direct-to-movie may help you streamline your operations and help your bottom line.

This may be significantly beneficial for firms that will need to provide orders swiftly or for people who give rush orders. You can produce and ship orders speedier, which may help you maintain your shoppers satisfied and happy.

Professional idea: If the style isn't tall, you could print it wider, as many as 14". If it's a sq. or circle, take into consideration decreasing the general measurement.

One of the greatest advantages of DTF heat transfers is the chance to generate more compact portions of garments. not like conventional screen printing, which demands a massive bare minimum order quantity, Direct-to-film heat transfers let you print as handful of or as several garments as you'll need.

For shirts for more youthful generations of teens or children, cutting down to seven″-9″ broad maintains Visible click here equilibrium. it is necessary to take into consideration shirt measurement and style and design complexity when figuring out the appropriate transfer size.